QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Project Background:

With the rapid development of industrial automation, more and more enterprises are seeking to upgrade their production lines through the introduction of intelligent robot technology. Among them, for the deburring process, Fuwei Intelligent uses 2D vision to guide the robot to perform circular motion, which can not only improve production efficiency, but also reduce labor costs and improve product quality. This solution aims to create a highly automated deburring process intelligent production line.

Project difficulty:

Different workpieces may have differences in shape, texture, lighting conditions, etc., which require high visual positioning accuracy;

Robots need to execute circular motion trajectories to complete deburring tasks, which requires the robot control system to be able to calculate and adjust the motion trajectory in real time;

The quality of deburring directly affects product quality and production line efficiency. How to achieve an efficient and stable deburring process, avoiding damage to the workpiece or leaving residual burrs, is the key issue that needs to be addressed in the project.

Solution:

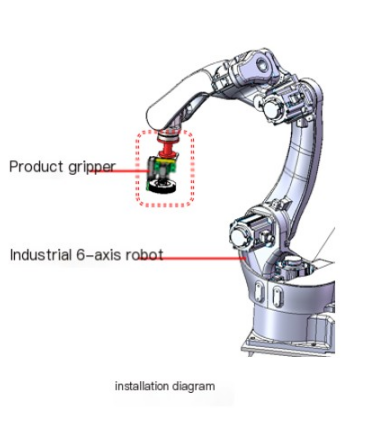

1. Complete the transformation relationship between the position of the product in the camera field of view and the position of the product in the robot coordinate system through "hand eye calibration";

2. By using visual guidance or robot teaching points, the camera can capture images on various surfaces of the object;

3. Using image distortion correction algorithms to achieve image changes caused by shooting from different angles;

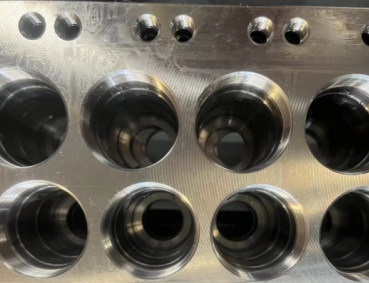

4. 2D camera recognition of product hole positions;

5. Generate four coordinate points based on the hole position;

6. The robot receives four coordinate points;

7 The robot connects four points in sequence through the "circular motion" command to complete circular hole cruising;

Core values:

This solution integrates a 2D vision system, high-precision robots, deburring tools, and intelligent control systems to achieve precise recognition, positioning, and automated deburring of workpieces. The robot automatically plans and executes a circular motion trajectory based on the position and posture information of the workpiece provided by the 2D vision system to complete the deburring task.

The automation upgrade of deburring process has been achieved by integrating 2D vision system, robot system, and intelligent control system. This solution not only improves production efficiency and reduces labor costs, but also enhances product quality and production line safety.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |