QR Code

About Us

Products

Contact Us

Phone

E-mail

In modern logistics and production lines, unpacking and palletizing cardboard boxes is one of the common operations. The traditional method of unpacking and palletizing relies on manual labor, which is inefficient and prone to errors. To solve this problem, Fuwei Intelligent has proposed an automated solution for cardboard box unpacking and palletizing based on 3D vision technology.

Scheme description

This scheme utilizes 3D vision sensors to capture three-dimensional images of cardboard boxes, and extracts geometric features and positional information of cardboard boxes through image processing algorithms. Then, based on this information, the control system can accurately plan the motion trajectory of the robotic arm or robot, achieving automatic unpacking and palletizing of cardboard boxes.

Advantages of the plan

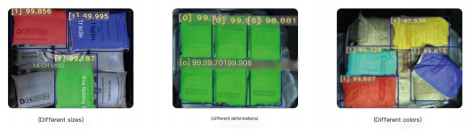

High precision recognition: 3D vision technology can accurately capture the three-dimensional shape and position of cardboard boxes, ensuring the accuracy of unpacking and palletizing.

High efficiency: Automated operations can significantly improve the speed of palletizing and reduce labor costs.

Flexibility: The system can adapt to cardboard boxes of different sizes and shapes without frequent adjustments.

Safe and reliable: reduce manual operation and avoid safety hazards.

This plan is expected to significantly improve the efficiency and quality of palletizing operations, reduce labor costs and safety risks, and create greater value for enterprises.

The automated solution for cardboard box unpacking and palletizing based on 3D vision technology is an effective means to solve the current problem of unpacking and palletizing, with broad application prospects and market potential.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |