QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

In the manufacturing industry, the crankshaft is an important mechanical component widely used in fields such as automobiles, ships, and generator sets. With the development of technology, the automation level of crankshaft manufacturing continues to improve, and 3D visual guidance technology provides a new solution for the automated feeding of crankshaft workpieces.

Project Background:

In modern manufacturing, crankshaft workpieces are a very important component widely used in fields such as automobiles, motorcycles, and ships. However, traditional manual feeding methods have low efficiency, difficulty in ensuring accuracy, and cannot meet production needs. Therefore, introducing robot technology has become an essential choice for enterprise production, achieving automation of crankshaft workpiece feeding in manufacturing through the use of robot technology and 3D vision.

Project difficulty:

Difficulty 1: The structure of the crankshaft workpiece is complex and irregular in shape, requiring high-precision positioning and attitude adjustment technology.

Difficulty 2: There are various types of crankshaft workpieces, and different models and specifications of crankshaft workpieces have significant differences in structure, size, and other aspects.

Solution

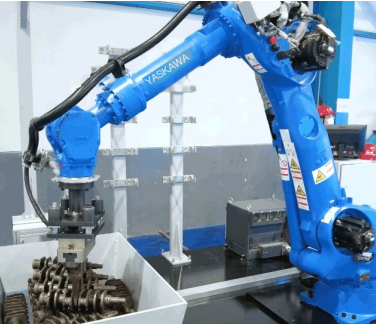

3D vision identifies and compares the shape, size, and other information of crankshaft workpieces, achieving automatic recognition of different models and specifications of crankshaft workpieces. By using computer processing technology to analyze images, the position coordinates and attitude angles of the crankshaft workpiece are calculated, providing accurate basis for subsequent grasping and feeding actions. The captured crankshaft workpiece can be quickly and accurately transported to the designated position and placed.

Advantages of the plan:

1. Improve production efficiency: Through an automated feeding system, the production efficiency of crankshaft workpieces can be significantly improved and the production cycle can be shortened.

2. Reduce labor costs: By adopting automated feeding, robots can replace manual labor, reduce labor and production costs, and improve the economic efficiency of enterprises.

3. Improve product quality: The automated feeding system can achieve precise control and stable production, effectively improving the product quality of crankshaft workpieces.

3D visual guidance technology has brought great convenience and development space to modern manufacturing industry. In the future, 3D visual guidance technology will play a greater role in the automation of crankshaft workpiece feeding, providing strong support for the transformation and upgrading of the manufacturing industry.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |