QR Code

About Us

Products

Contact Us

Phone

E-mail

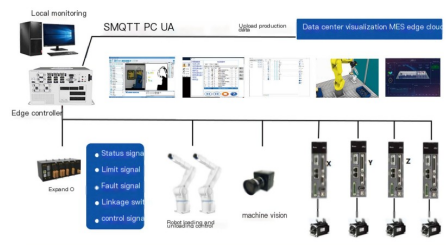

In today's digital age, intelligent manufacturing has become the key for enterprises to improve production efficiency and reduce costs. The reconfigurable flexible assembly production line is built on the Fuwei Intelligent AI Industrial Control and Decision Platform, which can control the entire system through an AI edge controller and achieve CNC automation assembly of cross category products. According to the assembly process of different products, the entire production line is composed of several identical assembly units connected in series or parallel, and then the assembly environment of each unit is reconstructed to achieve the maximum assembly line balance rate.

Technical solution for reconfigurable flexible assembly production line

Industry Status

1 Multi layer controller architecture redundancy

Traditional systems are composed of multiple controllers such as industrial control computers and PLCs, with a multi-layered architecture, large size, and low cost-effectiveness; At the same time, traditional architecture control layers have limited computing power and cannot efficiently process large amounts of data.

2 Multiple varieties in small batches, with a clear trend towards flexibility

In the era of personalized products, assembly products frequently change, and the industry commonly uses human-machine hybrid assembly lines to achieve cross category product assembly. However, manual assembly is prone to fluctuations in product assembly quality, high replacement cycles and costs of assembly lines, and low production line efficiency.

3 Multiple controller languages, high personnel requirements

Traditional automation equipment requires personnel from multiple aspects such as up and down machine development. Software needs to be deployed separately for each controller and requires code programming, with high personnel requirements.

4 Low standardization level and high usage cost

Multiple functional components need to be purchased, with significant differences between devices and different software for different devices, resulting in increased labor costs for debugging and use.

Software Introduction

Digital Factory Management System

The digital factory management system is an intelligent production execution system based on cloud deployment with high cost-effectiveness and real-time automatic reporting. It helps manufacturing enterprises improve product quality, reduce costs, achieve efficient operation, efficient collaboration, and realize digital intelligent factories.

Software feature introduction:

lower production cost

Through production process management, rational allocation of production resources, improvement of product quality, implementation of paperless management, elimination of waste in materials, manpower, time, transportation, etc., to create higher efficiency for the enterprise.

Visual Management

Real time understanding of the production line status, including current equipment status, production progress, process flow, production utilization rate, etc., presented through real-time reports and data screens, provides effective basis for production management analysis and continuous improvement in the later stage, and also makes the operation status of equipment such as process, production, quality, and machines controllable.

Product advantages

Support protocol - connect all aspects of the factory.

Integrated control

Zero code programming

The Fuwei reconfigurable flexible assembly production line adopts integrated control software and zero code programming based on edge control language. All modules are quickly deployed through process construction and configuration modes, allowing users to focus on the process flow rather than the underlying control logic.

The emergence of a comprehensive solution for reconfigurable flexible assembly production lines provides a new solution for intelligent production. It perfectly combines AI technology with edge controllers, improving the performance and efficiency of the system, and further enhancing the efficiency of industrial production.

-

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |