QR Code

About Us

Products

Contact Us

Phone

E-mail

Medical devices, as important products related to human life and health, require extremely high precision and safety in their production process. The application of collaborative robot loading and unloading technology provides precise and reliable solutions for medical device production.

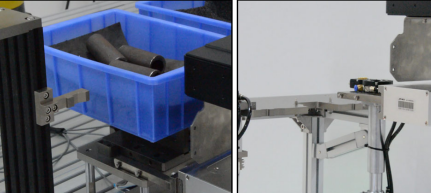

In the production process of medical devices, the loading and unloading of components require extremely high precision and stability. Collaborative robots can achieve precise positioning and grasping of components through high-precision sensors and control systems. Whether it's tiny screws or complex components, collaborative robots can easily handle them, ensuring that every component can be accurately placed in the designated position.

In addition, collaborative robots also have a high degree of cleanliness. In the production process of medical devices, it is often necessary to maintain a dust-free and sterile environment. Collaborative robots can operate stably in such environments, avoiding pollution risks caused by human factors.

Meanwhile, the flexible design of collaborative robots enables them to adapt to the production needs of different medical devices. Whether it is large-scale production lines or small-scale customized production, collaborative robots can be flexibly adjusted according to actual needs, providing a more efficient and accurate production method for medical device production.

In summary, the application of collaborative robot loading and unloading technology in different industries has demonstrated its unique advantages and potential. With the continuous advancement of technology and the expansion of application scenarios, we believe that collaborative robots will bring revolutionary changes to more industries in the future.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |