QR Code

About Us

Products

Contact Us

Phone

E-mail

Address

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Driven by the wave of informatization and intelligence, the manufacturing industry is facing unprecedented challenges in transformation and upgrading. Among them, the reconfigurable flexible assembly line provides a new solution for the intelligent transformation of the manufacturing industry with its unique AI edge control technology.

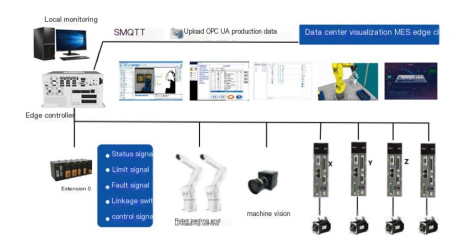

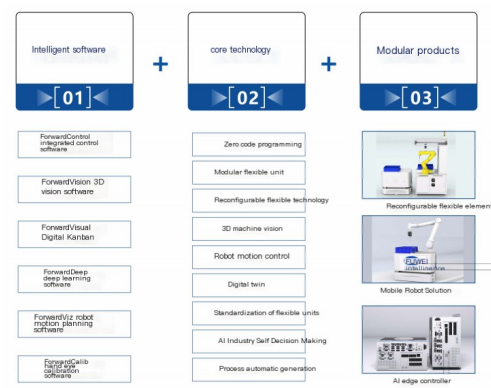

The reconfigurable flexible assembly production line is an intelligent production system built on an AI industrial control and decision-making platform. It controls the entire system through an AI edge controller, thereby achieving CNC automation assembly of cross category products. This design not only simplifies the system architecture and improves performance, but also greatly reduces production costs and maintenance difficulties.

AI edge controllers play a crucial role in reconfigurable flexible assembly lines. It has powerful data processing and analysis capabilities, capable of collecting and processing various data in real-time during the production process, providing strong support for production decisions. Meanwhile, by seamlessly connecting with other devices, real-time information sharing and collaborative work have been achieved, further improving production efficiency and quality.

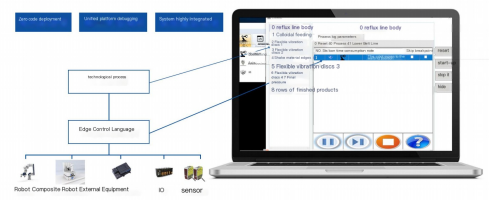

In addition to the application of AI edge controllers, the reconfigurable flexible assembly production line also adopts integrated control software with zero code programming. This software achieves rapid deployment through process building and configuration modes, allowing users to focus more on the process flow rather than the underlying control logic. This not only reduces the requirements for technical personnel, but also improves the flexibility and scalability of the system.

The application of reconfigurable flexible assembly lines has brought significant advantages to the manufacturing industry. Firstly, it can quickly adapt to product changes and meet the diverse needs of the market. By simple configuration and adjustment, assembly production of different products can be achieved, greatly shortening the production cycle and reducing costs. Secondly, it improves production efficiency and quality. Through intelligent control and optimization algorithms, the automation and refinement of the production process have been achieved, improving production efficiency and product quality. Finally, it also creates higher economic and social benefits for the enterprise. By reducing production costs, improving product quality, and meeting market demand, the company has gained more market share and profit margins.

Of course, the application of reconfigurable flexible assembly lines still faces some challenges and problems. For example, how to further improve the stability and reliability of the system, and how to reduce the maintenance cost of the system. But with the continuous advancement of technology and the accumulation of application experience, we believe that these problems will be effectively solved.

In summary, the reconfigurable flexible assembly line, as a new exploration of AI edge control technology, provides a new solution for the intelligent transformation of the manufacturing industry. It will bring more efficient, flexible, and intelligent production methods to the manufacturing industry, promoting its development to a higher level.

No. 22, Hongyuan Road, Guangzhou, Guangdong Province, China

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |