QR Code

About Us

Products

Contact Us

Phone

E-mail

In the fiercely competitive automotive manufacturing industry, improving production efficiency, reducing costs, and ensuring product quality are key to the sustainable development of enterprises. Especially in the process of automobile manufacturing, the loading and unloading operations of various components occupy a large amount of production time, so how to achieve automation and efficiency of these operations has become an urgent problem to be solved.

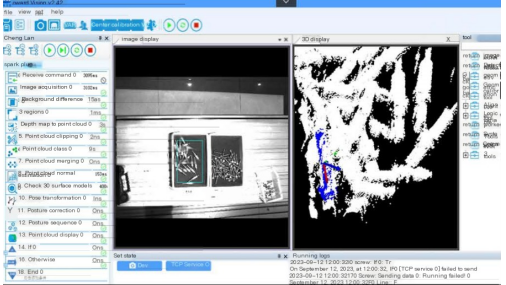

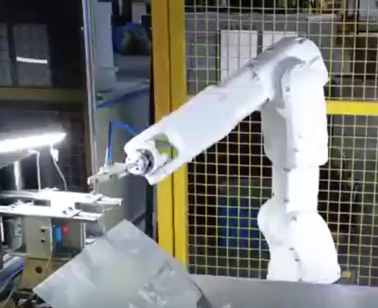

The Fuwei Intelligent 3D Vision Guided Robot mainly consists of three parts for grasping workpieces: the 3D vision system, the robot arm, and the control system. The system captures the position and posture information of the workpiece through a 3D camera, and the robot arm performs precise grasping and placement operations based on this information, while the control system is responsible for coordinating and optimizing the entire process.

3D Vision System: Utilizing high-resolution 3D cameras to capture real-time three-dimensional position and pose information of workpieces. This system has the characteristics of high precision and high speed, which can quickly and accurately identify workpieces and provide reliable data support for their subsequent grasping and placement operations.

Robot arm: Based on the information provided by the 3D vision system, the robot arm performs precise grasping and placement operations. The robot arm has high flexibility and accuracy, and can adapt to workpieces of different shapes and sizes, ensuring the accuracy and stability of operation.

Control system: Coordinate and optimize the entire process to achieve automated loading and unloading operations. The control system can adjust the gripping speed and position of the robot arm according to production needs, as well as optimize the path and sequence of loading and unloading, further improving production efficiency.

High precision grasping: Through the high-precision data provided by the 3D vision system, the robot arm can accurately recognize the position and posture of the workpiece, ensuring the accuracy of grasping and placement. This high-precision grasping not only improves production efficiency, but also reduces the risk of damage to the workpiece.

Flexible production: The Fuwei intelligent 3D vision system can adapt to the loading and unloading requirements of different models and specifications of automotive workpieces. By adjusting the parameters of the visual system and robot arm, it is easy to cope with product updates and production adjustments, achieving flexible production.

Improve production efficiency: Automated loading and unloading operations reduce manual intervention and improve production efficiency. At the same time, the control system can optimize the path and sequence of loading and unloading according to production needs, further shortening the production cycle.

Reduce costs: By reducing manual operations and minimizing the risk of damage to workpieces, the Fuwei intelligent 3D vision guided gripper system can lower production costs. In addition, the high-precision and flexible production characteristics of the system also reduce waste and rework rates during the production process.

Fuwei Intelligent 3D Vision Guided Robot has achieved flexible production in the automotive manufacturing process by grasping workpieces through advanced vision technology and robot technology.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |