QR Code

About Us

Products

Contact Us

Phone

E-mail

The precision manufacturing industry has extremely high requirements for equipment accuracy, stability, and efficiency, and composite robots are gradually becoming the new favorite in this field due to their multifunctionality, high flexibility, and precise control capabilities. The following is an application case of Fuwei Intelligent Composite Robot in precision manufacturing.

Case background

A well-known automotive parts manufacturing enterprise focuses on producing high-precision and high-quality engine components. In order to cope with the rapid growth of market demand and enhance product competitiveness, the company has decided to introduce composite robots to optimize the production line, improve production efficiency and product quality.

Application plan

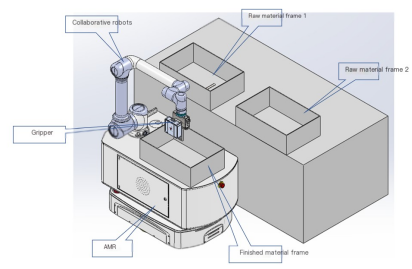

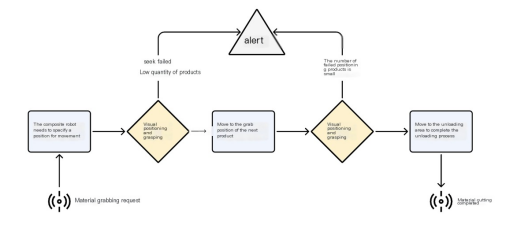

The company has introduced multiple Fuwei intelligent composite robots for precision machining and assembly of engine components. These composite robots are equipped with high-precision robotic arms, advanced vision systems, and intelligent control systems, which can achieve precise grasping, positioning, and assembly of components.

On the production line, composite robots seamlessly integrate with CNC machine tools, detection equipment, etc., forming a highly automated production line. The composite robot automatically completes tasks such as loading and unloading, processing, and inspection of components according to preset programs and instructions. At the same time, real-time inspection of components is carried out through a visual system to ensure that each component meets quality standards.

In addition, the Fuwei intelligent composite robot also has high flexibility and scalability. Enterprises can easily adjust the quantity and configuration of robots according to production needs to adapt to the production of different models and specifications of components.

Application effect

After introducing composite robots, the production efficiency of the enterprise has been significantly improved. The automation of composite robots reduces the complexity and errors of manual operations, and improves the stability and reliability of production lines. Meanwhile, the high-precision operation of the composite robot also ensures the stability and consistency of product quality.

In addition, the introduction of composite robots has also reduced the production costs of enterprises. Due to the fact that robots can work 24 hours a day without interruption, companies do not need to worry about

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |