QR Code

About Us

Products

Contact Us

Phone

E-mail

With the continuous development of industrial automation technology, reconfigurable assembly lines, as a flexible and intelligent production method, are gradually becoming the future trend of industrial manufacturing.

The concept of reconfigurable assembly line

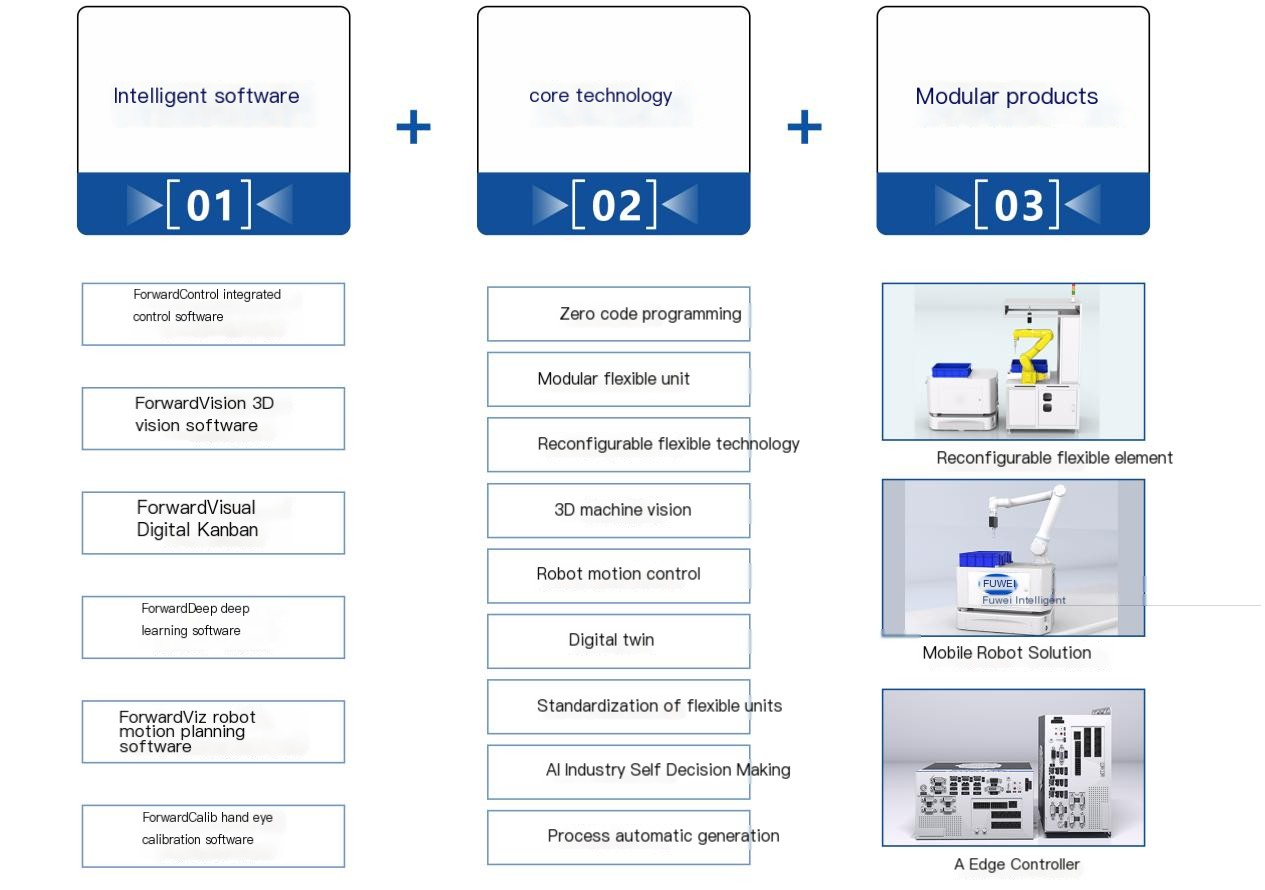

A reconfigurable assembly line refers to a production line system that can be flexibly adjusted and reconfigured according to production needs and product changes. It adopts modular design and intelligent control technology, enabling the production line to quickly adapt to different product types, process requirements, and production scales, achieving high efficiency and flexibility in the production process.

The advantages of reconfigurable assembly lines

High flexibility: The reconfigurable assembly line can quickly adjust and reconfigure according to product types and production needs, supporting multi variety and small batch production, reducing production conversion costs and time.

Intelligent control: Through advanced sensor technology, artificial intelligence algorithms, and real-time monitoring systems, the reconfigurable assembly line can achieve automated operation, real-time monitoring, and intelligent optimization adjustment, improving production efficiency and quality.

Production Transparency: The reconfigurable assembly line realizes data-driven and information-based management of the production process, supports real-time monitoring, analysis, and mining of production data, and provides data support for enterprise decision-making.

The application prospects of reconfigurable assembly lines

Reconfigurable assembly lines have broad application prospects in multiple industries, especially in the following areas:

Automotive manufacturing: Reconfigurable assembly lines can adapt to the diverse and customized needs of automotive products, support vehicle model changes and process adjustments, and improve the flexibility and efficiency of automotive manufacturing.

Electronic products: Faced with the fast updating and upgrading characteristics of electronic products, reconfigurable assembly lines can quickly adjust the layout and process flow of the production line, maintaining the competitiveness and flexibility of the production line.

Medical equipment: Reconfigurable assembly lines can meet different product specifications and functional requirements in medical equipment manufacturing, support rapid response to market demand changes, and improve production efficiency and quality.

As an important component of industrial intelligent manufacturing, reconfigurable assembly lines will bring more efficient, flexible, and intelligent production methods to enterprises in the future, helping industrial manufacturing transform towards intelligence and digitization.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |