QR Code

About Us

Products

Contact Us

Phone

E-mail

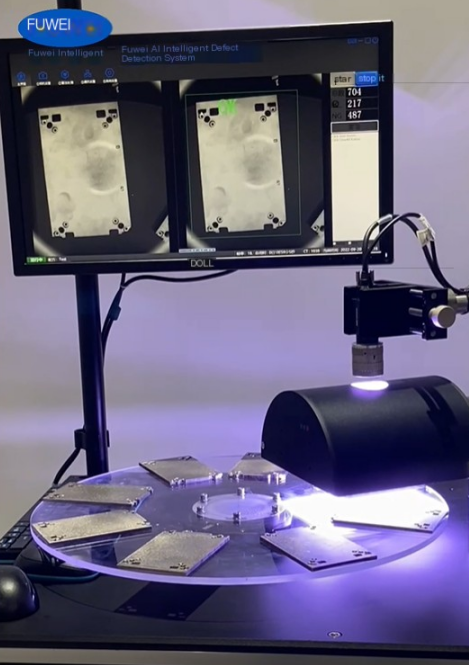

Machine vision defect detection is a key technology in the field of industrial automation, which can significantly improve production efficiency and product quality. However, in practical applications, machine vision defect detection faces many challenges. Here is a detailed analysis of these challenges:

Large amount of data and slow processing speed: In actual production lines, the amount of image data that needs to be detected is often very large, which puts extremely high demands on processing speed. Traditional machine vision algorithms may encounter performance bottlenecks when processing large amounts of data, resulting in reduced detection speed and affecting the efficiency of production lines.

The diversity of defect types: Different products may have various types of defects, and the types are extremely complex. For example, surface scratches, stains, uneven colors, deformations, etc. all pose great challenges to defect detection. How to design a universal detection system that can accurately identify various defects is a major challenge in the field of machine vision.

The impact of lighting and environmental changes: In actual production environments, lighting conditions and environmental factors are often uncertain, which directly affects the quality of the collected images and thus affects the accuracy of defect detection. For example, strong light or shadows may cause certain areas to be overexposed or underexposed in the image, resulting in the inability to identify defects within them.

Background noise and interference factors: Background noise on the production line, mutual occlusion between products, and various interference factors such as dust, water droplets, etc., may all interfere with defect detection. How to eliminate these interferences and improve the robustness of detection is another challenge faced by machine vision defect detection.

Scalability and adaptability of algorithms: With the upgrading of production lines or changes in products, defect detection algorithms need to be able to adapt to new situations. This requires algorithms to have a certain degree of scalability and adaptability, and to be able to self adjust and learn based on new data and environmental conditions.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |