QR Code

About Us

Products

Contact Us

Phone

E-mail

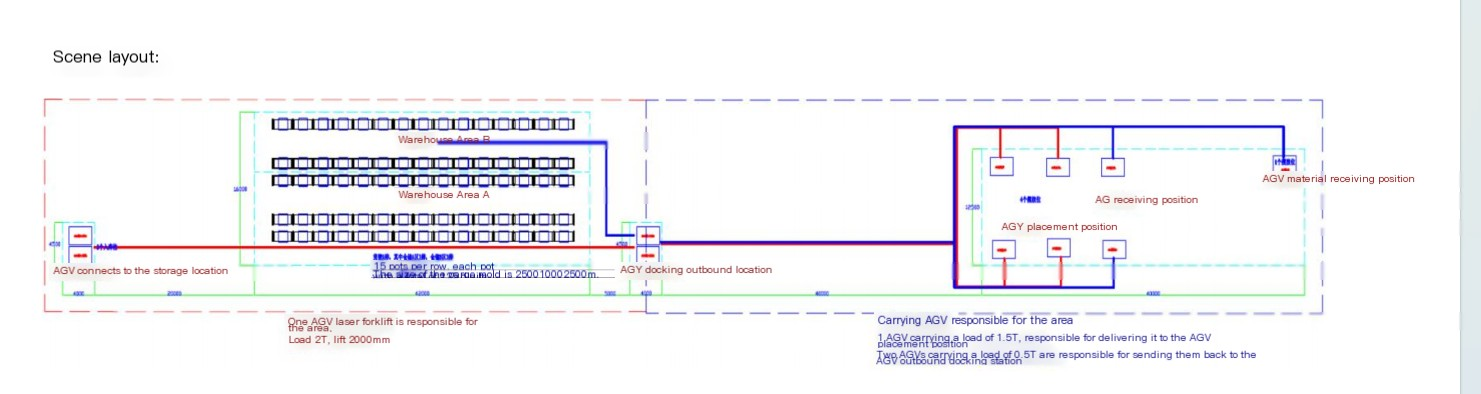

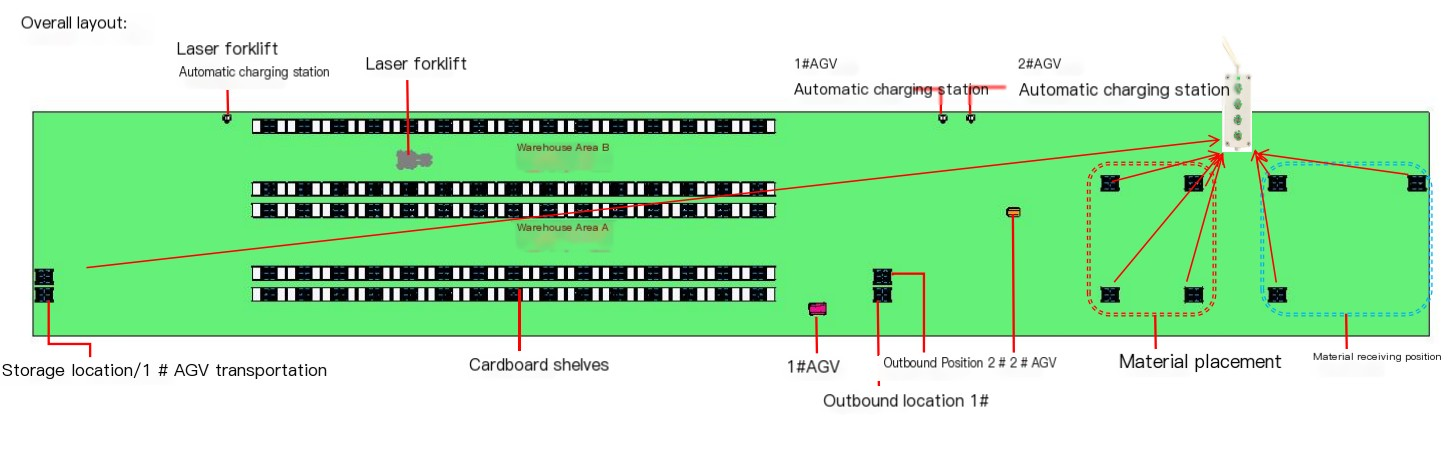

The aim of this project is to achieve automated transportation and warehouse management of pallets. By introducing two types of automated equipment, AGV and laser forklift, transportation efficiency is improved, manual intervention is reduced, and the process is ensured to be smooth and safe.

Product Characteristics and Requirements Analysis

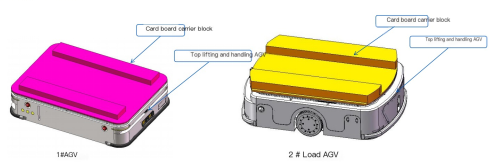

Considering that the product is a single type of card board with a specification of 1200mm * 1000mm, we have chosen the lifting and handling trolley and laser forklift as the core equipment for the solution. The lifting and handling trolley can select different transportation routes based on manual signals to achieve flexible handling of pallets; Laser forklifts are responsible for warehouse management and the inbound and outbound operations of pallets, ensuring the accuracy and efficiency of inventory.

Workflow Design

Working process of lifting and transporting trolley:

Manually code the materials onto the pallet and specify the storage and material placement positions through call signals;

After receiving the signal, AGV 1 # travels from the standby position to the storage position, lifts the pallet through the lifting mechanism, and transports it to the material placement position;

When the storage position is idle, AGV 1 # can continue to receive new handling tasks or return to the standby position to wait;

All channels are reserved with sufficient space to ensure that two AGVs can perform U-turns simultaneously.

Laser forklift workflow:

When there are pallets waiting to be transported in the storage area, the laser forklift moves from storage area A to the storage area, and uses laser navigation to accurately locate and transport the pallets to the outbound location 1 #;

When the material placement position is idle, the laser forklift will transport the pallet from position 1 to the material placement position for subsequent operations;

Laser forklifts are also responsible for handling pallets between storage areas A and B, ensuring timely replenishment and adjustment of inventory;

Laser forklifts are highly automated and intelligent, capable of automatically planning the optimal path and improving handling efficiency.

Equipment configuration and advantages

Top lifting and handling trolley:

Adopting high-precision navigation and positioning technology to ensure the accuracy and stability of transportation routes;

The lifting mechanism is designed reasonably and can adapt to the transportation needs of different heights and loads of pallets;

Equipped with flexible communication interfaces for easy linkage with manual signals or other devices.

Laser forklift:

Laser navigation technology ensures that forklifts can accurately locate and navigate in complex environments;

Capable of efficient handling speed and stability, able to meet the rapid response needs of warehouse management;

Through an intelligent management system, real-time updates and queries of inventory can be achieved, improving the transparency and accuracy of warehouse management.

By introducing lifting and handling carts and laser forklifts, this project has achieved automated transportation and warehouse management of pallets, improved transportation efficiency and accuracy, and reduced labor costs and error rates.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |