QR Code

About Us

Products

Contact Us

Phone

E-mail

As a highly integrated and intelligent device, composite robots also have broad prospects for application in the field of magnetic steel production. At present, many magnetic steel production enterprises still use traditional manual loading and unloading methods, which are not only inefficient but also susceptible to human factors, leading to unstable product quality. At the same time, with the intensification of market competition, enterprises have increasingly high requirements for production efficiency and quality, and traditional production methods are no longer able to meet market demand. The client is an intelligent manufacturing industry and hopes to transform old robots into composite robots through Fuwei Intelligence for magnetic steel loading and unloading.

Pain points of traditional magnetic steel loading and unloading:

1 High dependence on manual operation: Traditional cutting processes often rely heavily on manual operations, including the handling, positioning, and placement of magnetic steel. This not only increases labor costs, but is also susceptible to human factors, leading to unstable operational accuracy and efficiency.

2 Operational safety issues: Magnetic steel has strong magnetism, and if accidentally operated manually, it may cause safety accidents such as hand gripping and impact, posing a threat to the safety of operators.

3 Low production efficiency: Due to the reliance on manual operation, the speed and efficiency of loading and unloading are limited, making it difficult to meet the large-scale and high-efficiency production needs.

4. Unstable quality control: Manual operation may lead to inaccurate positioning and uneven placement of magnetic steel, thereby affecting the quality of subsequent processing or assembly.

5. Work environment issues: During the loading and unloading process of magnetic steel, environmental pollution such as dust and noise may be generated, which may have a certain impact on the work environment and the health of operators

Customer requirements:

Composite robots complete the loading and unloading of two types of products

Rhythm requirement: Complete the loading of two stacks of products in about 80 seconds

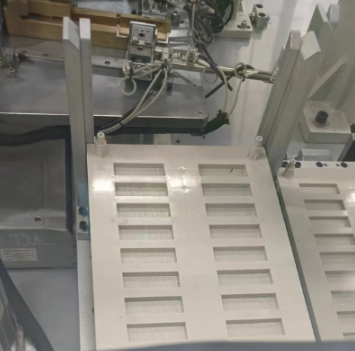

Accuracy: As shown in the figure (with guidance)

Product size310 * 210 * 10 (excluding magnetic steel)

Renovation plan1 Composite robot

Replace the motor:

Select high-performance motors that match the structure of the robot to ensure that the output torque and speed meet the requirements for grasping and moving magnetic steel.

The motor should have high reliability and durability to adapt to long-term, high-intensity working environments.

Replace servo controller:

Select servo controllers with high-precision control algorithms to achieve precise control of motor motion.

The servo controller should have fast response and stable performance to ensure the accuracy and stability of the robot when performing complex actions.

Radar navigation:

Equipped with high-precision radar sensors to achieve autonomous navigation and positioning of robots.

By scanning the surrounding environment with radar, an environmental map is constructed to achieve path planning and obstacle avoidance functions.

Light belt:

Install LED light strips in key parts of the robot to improve its visibility and recognition.

The light strip should have sufficient brightness and uniformity to ensure effective illumination of the working environment under different lighting conditions.

Speaker:

Install an alarm horn to sound an alarm in emergency situations.

Meanwhile, speakers can be used for voice prompts, facilitating interaction between operators and robots.

Gripper (with camera and other sensors):

Design customized specialized grippers to ensure stable and accurate gripping of magnetic steel.

Integrating high-definition cameras and force sensing, tactile and other sensors on the gripper to achieve precise recognition of magnetic steel and control of gripping force.

2、 Loading area

Positioning guide groove:

Design positioning guide slots to guide magnetic steel into designated positions, facilitating robot grasping.

The guide groove should have sufficient accuracy and stability to ensure that the magnetic steel can be accurately placed in the preset position.

Desktop positioning Mark:

Set clear positioning Mark marks on the loading area desktop for robot recognition and positioning of gripping points.

The Mark mark should have clear and easily recognizable characteristics to ensure that the robot can accurately recognize it under different lighting conditions.

3、 Material unloading area

Equipment positioning Mark:

Set up positioning Mark markers on the equipment in the unloading area for robot recognition and positioning of placement points.

The design of the Mark mark should take into account the structure and size of the equipment to ensure that the robot can accurately place the magnetic steel in the designated position.

Electric control panel door:

Install electric control panel doors in the unloading area to protect robots and operators from accidental injuries.

The protective panel door should have quick response and automatic closing functions to ensure that it can automatically close when the robot is working, preventing personnel from entering the dangerous area.

Electric control push-pull slot:

Design an electrically controlled sliding groove for pushing equipment or trays with magnetic steel out of the unloading area.

The sliding groove should have smooth and reliable motion performance to ensure that the magnetic steel or equipment will not be damaged during the pushing process.

Through the above transformation plan, the composite robot will be able to achieve automatic loading and unloading of magnetic steel, improving production efficiency and quality stability. Meanwhile, by optimizing the layout and equipment configuration of the loading and unloading areas, the robot can ensure accurate and efficient completion of tasks.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |