QR Code

About Us

Products

Contact Us

Phone

E-mail

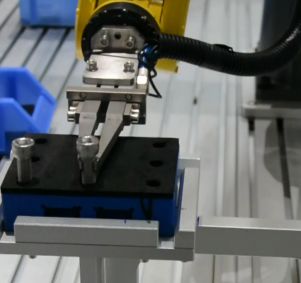

In today's highly automated manufacturing environment, precise and efficient processing of automotive parts is crucial. Especially in the 3C industry, such as the manufacturing process of mobile phones, computers, and other products, the loading and unloading of small parts has become a technical challenge. Fuwei Intelligent 3D Vision Guided Grasping System helps automotive manufacturing achieve flexible production.

Overview of the Plan

Fuwei Intelligent's solution mainly utilizes 3D vision systems, robot arms, and control systems to achieve automated loading of workpieces. By capturing the position and posture information of the workpiece through a 3D camera, the robot arm accurately grasps and places it based on this information, while the control system is responsible for coordinating and optimizing the entire process.

Advantages of the plan

Through the 3D vision system, the position and orientation information of the workpiece can be accurately obtained, with errors controlled within a very small range, ensuring the accuracy of grasping and placement;

By adjusting the parameters of the visual system and robot arm, it is possible to adapt to the loading and unloading requirements of different models and specifications of automotive workpieces, and easily cope with product updates and production adjustments.

Fuwei Intelligent's solution based on 3D vision guidance not only improves production efficiency and reduces costs, but also ensures product quality and safety.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |