QR Code

About Us

Products

Contact Us

Phone

E-mail

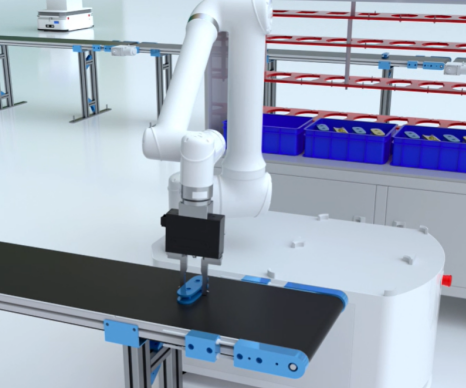

Fuwei Intelligent Composite Robot is a combination of collaborative robots, mobile robots, and visual guidance technology, equipped with ICD series core controllers. Through flexible integration of multiple functions such as "hands, feet, eyes, and brain", it can meet the collaborative handling needs of various complex scenarios.

The popularity of composite robots in warehousing is not only due to their high efficiency and accuracy, but also because they have brought revolutionary changes to warehousing management. These robots can achieve intelligent scheduling and optimized configuration of goods through intelligent algorithms and data analysis, greatly improving the utilization of storage space. In addition, composite robots can seamlessly integrate with other warehousing equipment and systems, achieving automation and intelligence of the warehousing process, thereby greatly improving overall operational efficiency.

At the same time, the application of composite robots has also driven the digital transformation of the warehousing industry. By collecting and analyzing the operational data of robots, enterprises can gain a deeper understanding of the situation of warehousing operations, identify potential problems, and optimize them in a timely manner. This digital transformation not only improves the transparency of warehouse management, but also provides more decision support for enterprises, helping them better cope with market changes and challenges.

Advantages of Composite Robots:

1. Improve production efficiency: Composite robots can quickly and accurately complete various tasks through automation and intelligence, greatly improving production efficiency. They can work continuously within 24 hours and operate accurately without errors, avoiding the impact of human factors on production speed.

2. Cost reduction: The use of composite robots can effectively reduce labor costs, as robots can replace manual labor to complete some heavy, dangerous, or high-risk tasks. In addition, due to the accurate operation of robots, it can also reduce production losses and maintenance costs caused by human errors.

3. Enhance safety: In some dangerous or harmful environments, the use of composite robots can greatly reduce the risk of injury to workers. For example, using specialized human-machine collaborative grippers can reduce the risk of injury and infection.

4. Improve flexibility: Composite robots can be associated and interact with other automation system equipment, achieving collaborative work with humans. This flexibility enables them to adapt to a wider range of work challenges and complete more complex and flexible work tasks.

5. Improve product quality: Due to the accurate and error free operation of robots, it can avoid the influence of human factors on product quality, thereby improving product consistency and stability.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |