QR Code

About Us

Products

Contact Us

Phone

E-mail

With the continuous improvement of intelligence and automation in the manufacturing industry, the precise and efficient feeding process of the inertia ring, as the core component of automotive engine shock absorbers, is particularly crucial. As an important technical means to achieve this goal, the application prospects of 3D vision technology in the field of inertial ring feeding are very broad. This article will explore the future development of 3D vision technology in the field of inertial ring feeding from the perspectives of technological innovation, application scenario expansion, and system integration.

1、 Technological innovation leads future development

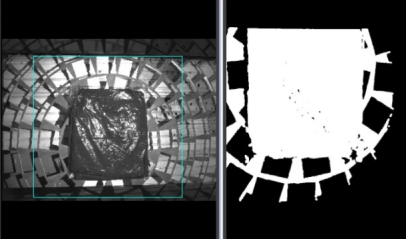

In the future, 3D vision technology will achieve new breakthroughs in imaging quality, processing speed, algorithm optimization, and other aspects. With the continuous advancement of imaging technology, 3D cameras will be able to capture finer and richer three-dimensional spatial information, providing a more solid foundation for precise identification and positioning of inertial rings. Meanwhile, with the improvement of computing power and continuous optimization of algorithms, 3D vision systems will achieve significant improvements in processing speed and accuracy, meeting the higher requirements for real-time and precision on production lines.

2、 The application scenarios are constantly expanding

With the continuous development of 3D vision technology, its application scenarios in the field of inertial ring feeding will also continue to expand. In addition to the traditional automotive manufacturing field, 3D vision technology will also be applied to high-end manufacturing industries such as aerospace and rail transit, achieving precise grasping and placement of inertial rings of various complex shapes and materials. In addition, with the integration and application of technologies such as the Internet of Things and big data, 3D vision technology will also play an important role in intelligent warehousing, logistics automation, and other fields, promoting the overall level of intelligence in the manufacturing industry.

3、 System integration has become a trend

In the future, 3D vision technology will be more closely integrated with robotics, sensor technology, cloud computing, and other technologies to form a highly integrated intelligent production system. In such a system, 3D vision technology will serve as a key perception tool to provide precise target positioning and posture recognition information for robots, achieving automation and intelligent feeding of inertial loops. Meanwhile, through cloud computing and big data technology, the system can achieve real-time analysis and optimization of production data, further improving production efficiency and product quality.

With the diversification and individualization of market demand, flexible production has become an important development direction for the manufacturing industry. Inertial rings, as key components in industries such as automobiles and aerospace, have higher requirements for the flexibility of production lines due to their diverse product specifications and fast update speed. In the future, 3D vision technology will pay more attention to compatibility and rapid adaptability to multiple specifications. Through algorithm optimization and system integration, it will achieve automatic recognition and grasping of inertia rings of different specifications, meeting the flexibility requirements of production lines.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |