QR Code

About Us

Products

Contact Us

Phone

E-mail

With the rapid development of intelligent manufacturing technology, the application of automated production lines in the field of magnetic steel production is becoming increasingly widespread. However, traditional manual loading and unloading methods have many problems, such as low efficiency, unstable quality, safety hazards, etc., which are no longer able to meet the needs of modern production. Fuwei Intelligence has proposed a composite robot solution for loading and unloading magnetic steel, aiming to improve production efficiency, reduce labor costs, and ensure operational safety through intelligent means.

Industry pain points

Low production efficiency: relying on manual operation, it is difficult to improve efficiency.

Unstable quality: The accuracy and consistency of manual operations are difficult to guarantee.

Major safety hazards: accidents such as hand pinching and impact are prone to occur during operation.

Poor working environment: poses a potential threat to the health of operators.

Overview of Customer Needs and Solutions

Customer demand: We hope to achieve automatic loading and unloading of magnetic steel through intelligent means, in order to improve production efficiency and quality stability. The specific requirements include completing the loading and unloading of two types of products, with a cycle time of about 80 seconds to complete the loading and unloading of two stacks of products, and having high precision requirements.

Solution Overview:

Replacing motors and servo controllers: Improving robot performance and stability.

Equipped with radar navigation, light strips, and speakers: enhancing the robot's autonomous navigation, visibility, and interactivity.

Design customized gripper: integrate camera and sensor to achieve precise recognition and grasping of magnetic steel.

Optimize the layout and equipment configuration of the loading and unloading areas to ensure that robots can accurately and efficiently complete their work.

Implementation and optimization of the plan

Composite robot transformation:

Select high-performance motors and servo controllers to ensure the accuracy and stability of motion.

Equipped with radar navigation to achieve autonomous positioning and path planning.

Install LED light strips and alarm speakers to improve visibility and interactivity.

Design customized grippers that integrate cameras and sensors to achieve precise identification and gripping of magnetic steel.

Optimization of loading area:

Design positioning guide slots to guide magnetic steel into designated positions.

Set up desktop positioning markers to facilitate robot recognition and positioning of grasping points.

Material unloading area renovation:

Set the device positioning Mark to ensure the robot accurately places the magnet.

Install electric control panel doors and electric control sliding slots to protect operators from injury and achieve automated equipment ejection.

Execution logic and process optimization

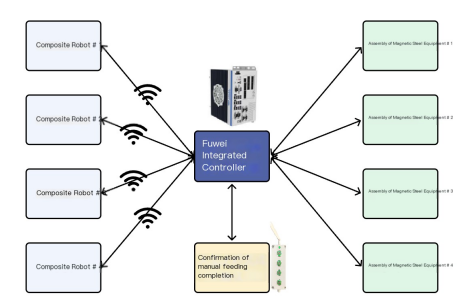

The execution logic of the entire plan is based on the process design of the automated production line, ensuring the continuity and efficiency of the workflow. The entire process is triggered by a loading request, and the robot performs material retrieval operations based on the status of the loading area. During the process of picking and placing materials, precise recognition and force control are achieved through cameras and sensors integrated into the gripper. Once the magnet is successfully placed on the equipment, the robot will confirm the completion of loading and proceed to the next cycle.

By using the Fuwei intelligent composite robot for magnetic steel loading and unloading, it can effectively solve the problems of traditional manual loading and

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |