QR Code

About Us

Products

Contact Us

Phone

E-mail

With the continuous advancement of technology and the rapid development of industry, intelligence and automation technology have become the two core driving forces for the advancement of modern industry. The integration of the two not only greatly improves production efficiency, but also brings unprecedented changes to the manufacturing industry. In this trend, the Fuwei Intelligent AI Edge Controller has become an important tool for achieving the integration of intelligence and automation due to its outstanding full-featured features.

1、 The trend of integration of intelligence and automation

In today's industrial production, the integration of intelligence and automation has become an irreversible trend. Intelligent technology provides more accurate and efficient decision support for the production process through methods such as data analysis and machine learning; Automation technology, on the other hand, achieves automated control of the production process through devices such as robots and sensors. The combination of the two not only improves production efficiency and product quality, but also reduces labor costs, providing strong guarantees for the sustainable development of enterprises.

2、 Full functional features of Fuwei Intelligent AI Edge Controller

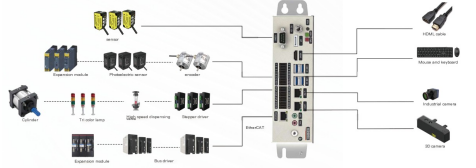

As an IPC based product based on x86 architecture, the Fuwei Intelligent AI Edge Controller fully utilizes the system's scalability, inheritability, multi domain, informatization, openness, and visualization features through PC based technology. At the same time, with the independently developed and controllable domestic real-time motion soft core of Fuwei Intelligence, the IPC form product has been transformed into a real-time motion controller or PLC, which has powerful motion control functions.

Powerful motion control function

Fuwei Intelligent AI Edge Controller supports various motion control modes such as single axis constant speed, variable speed motion, T-shaped S-shaped curve motion, interpolation motion, etc., which can meet the needs of motion control in different scenarios. At the same time, it also supports advanced functions such as multi axis interpolation, linkage, and synchronous motion, enabling more complex motion trajectory control. In addition, functions such as electronic cam, electronic gear, position latch, and comparison output also provide more possibilities for its application in the field of motion control.

Machine vision functionality

In addition to motion control functions, the Fuwei Intelligent AI Edge Controller also integrates machine vision functions. Through built-in image processing algorithms and high-speed image acquisition interfaces, it can achieve real-time analysis and processing of images during the production process. This feature makes the Fuwei Intelligent AI Edge Controller have broad application prospects in fields such as quality inspection and object recognition.

HMI and ladder diagram development

In order to meet the development needs of different users, the Fuwei Intelligent AI Edge Controller also supports the development of HMI and ladder diagrams. Users can achieve remote monitoring and control of devices through simple programming and configuration. This feature not only improves the usability of the device, but also provides users with more development options.

Real time kernel and high-performance hardware

The Fuwei Intelligent AI Edge Controller adopts self-developed Windows motion control real-time soft core, combined with x86 high-performance CPU and other hardware, to achieve high-speed and stable operation. It supports a minimum cycle time of 100us and can meet the requirements of high real-time control. At the same time, the industrial grade design enables it to operate stably in a wide temperature environment of -20~75 ° C, and has IP40 protection level and EMC level three protection capability, ensuring the reliability and stability of the equipment in harsh environments.

Copyright © 2024 Guangzhou Fuwei Electronic Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |